founder

When does Low Volume Production using the Prototyping Process make sense?

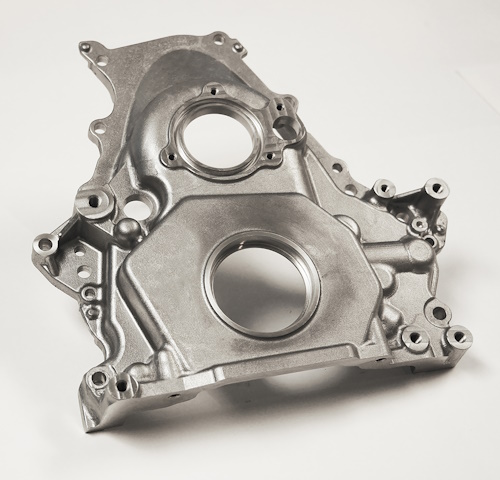

Aluma Cast Foundry

You only need a couple hundred parts, but your die casting die or permanent mold is no longer available. Aluma Cast’s low volume casting process may be a viable option for you.

section-f99468c

In the prototyping process there are things that can be done to give you enough production castings without breaking the bank.

If you need to get production parts quickly, then low volume production of parts via the prototyping process can be a viable solution. You will have to weigh the benefits of having production parts on time versus holding up production.

The per-part cost can vary substantially in low volume production depending upon the prototype process. Some prototyping processes are prohibitively expensive to consider for low volume runs. But even if you think you will not need a small volume of production parts it is worthwhile to discuss this possibility up front. Aluma Cast can offer you cost references so that you are prepared if the need arises.

The prototype casting process becomes suitable as a production casting process when the overall quantities you require do not justify the cost of expensive production tooling. Depending upon the size and complexity of the casting quantities of 300 to 500 castings a year is generally the volume that is cost-effective in Aluma Cast Foundry’s fine-grain sand casting process. Further processing may include heat treatment, machining, and coating to end up with a part that looks like a die casting and closely mimics the mechanical and/or physical properties of the eventual die cast product.