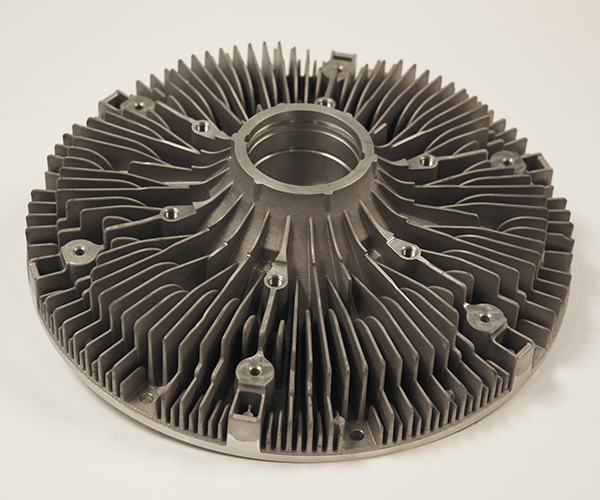

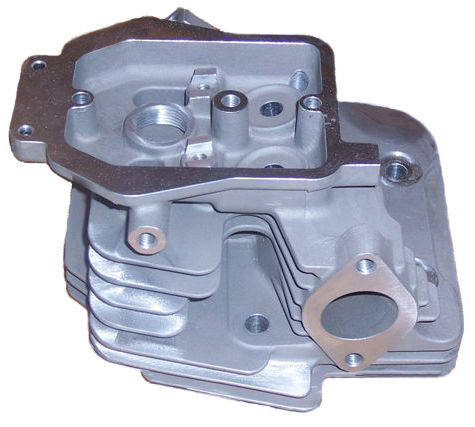

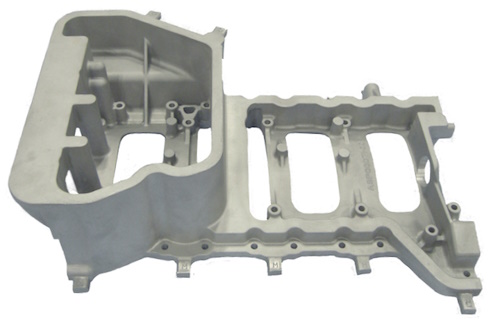

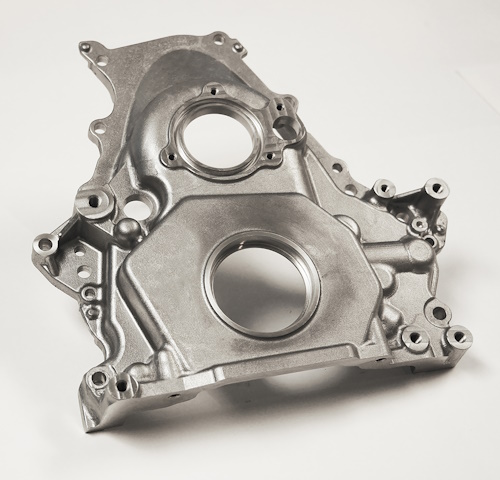

Thin Wall Aluminum Prototype Castings

Aluma Cast Foundry

Thin-wall prototype castings can present a challenge in the prototype casting world, but that does not mean that thin-wall parts cannot be cast and properly tested in the prototyping processes. The engineer should never be asked to revise the design of the part to accommodate the limitations of a selected prototyping process. Instead of changing the design to meet prototype process limitations, we recommend working with a prototype process that can produce prototype castings that truly reflect the performance characteristics of the die cast production process.